1. Introduction

In the realm of fluid dynamics and pumping systems, the placement and configuration of components play a critical role in ensuring efficiency, safety, and longevity. One often overlooked but crucial aspect is the distance between the pump suction port and any elbows in the piping system. In this blog post, we’ll delve into the potential dangers associated with using an elbow too close to the pump suction port and why maintaining the right distance is paramount.

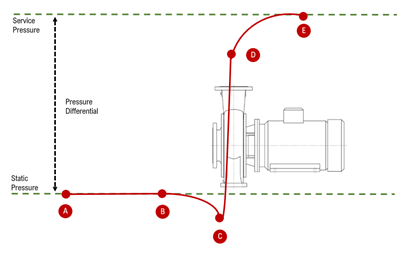

2. Understanding Pump Suction Dynamics

Pump suction dynamics involve the flow of fluid into the pump’s impeller. The goal is to create a smooth and uninterrupted flow, allowing the pump to operate efficiently. When elbows are introduced too close to the suction port, they can disrupt the natural flow pattern, leading to a host of problems.

3. Cavitation Concerns:

One of the primary dangers of having an elbow too close to the pump suction port is the increased risk of cavitation. Cavitation occurs when the pressure of the fluid drops below its vapor pressure, causing bubbles to form. As these bubbles collapse, they generate shock waves that can erode pump components, reducing efficiency and causing premature failure.

4. Vortex Formation

Placing an elbow too close to the suction port can also contribute to vortex formation. Vortices are swirling flows of liquid that can lead to air ingestion, causing additional problems such as reduced pump performance and potential damage to the impeller.

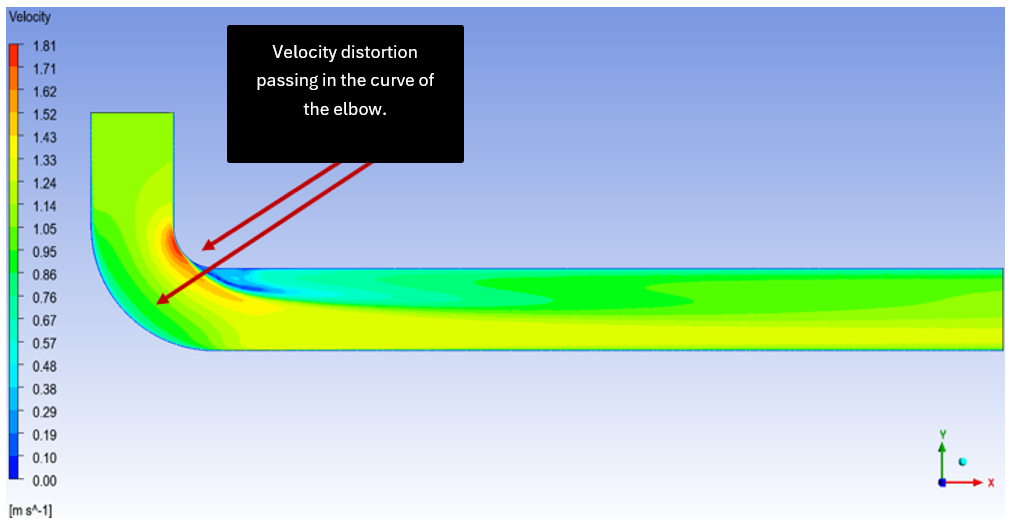

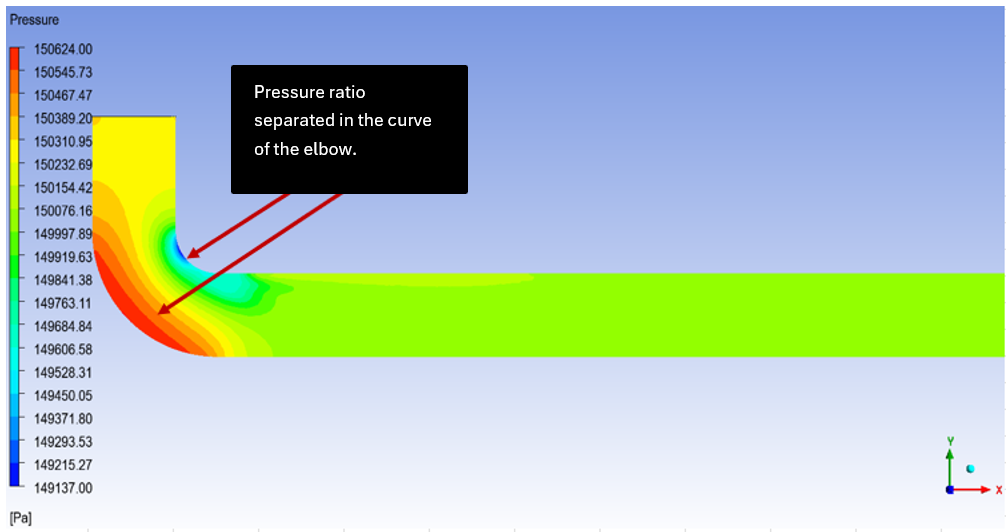

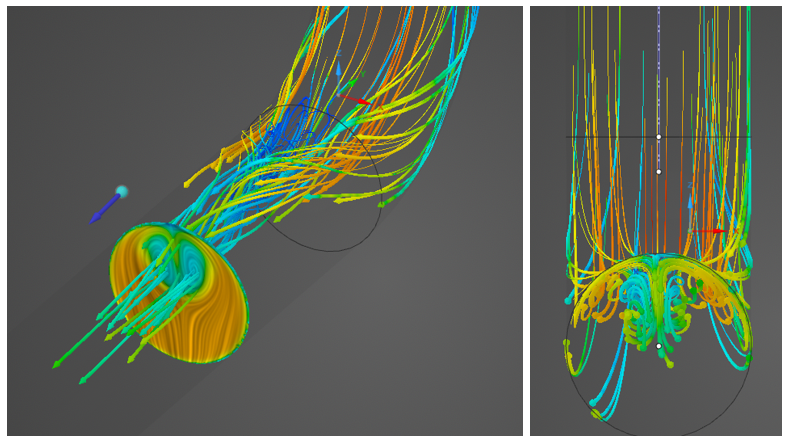

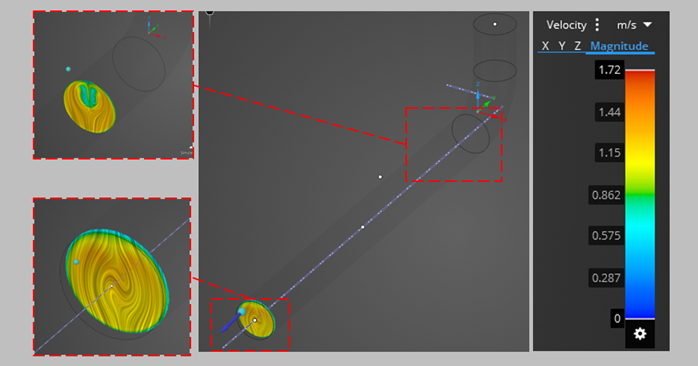

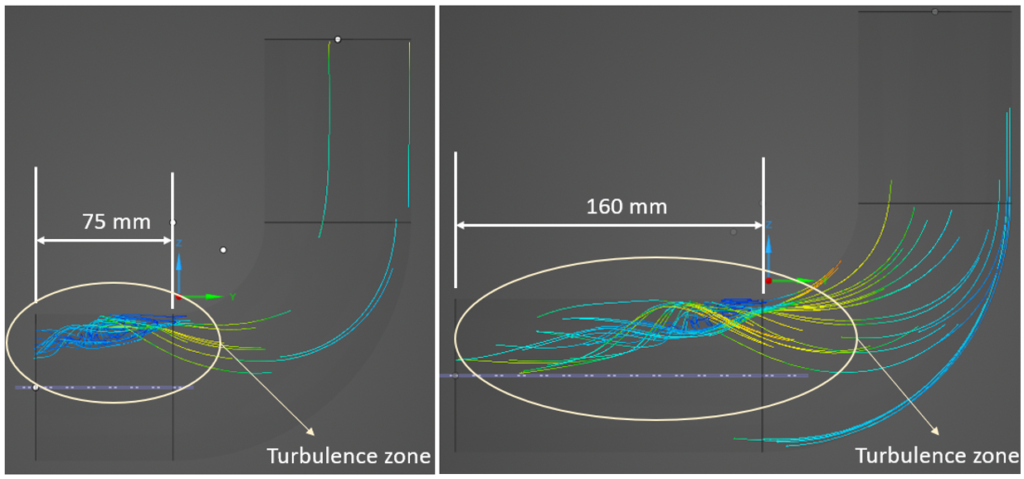

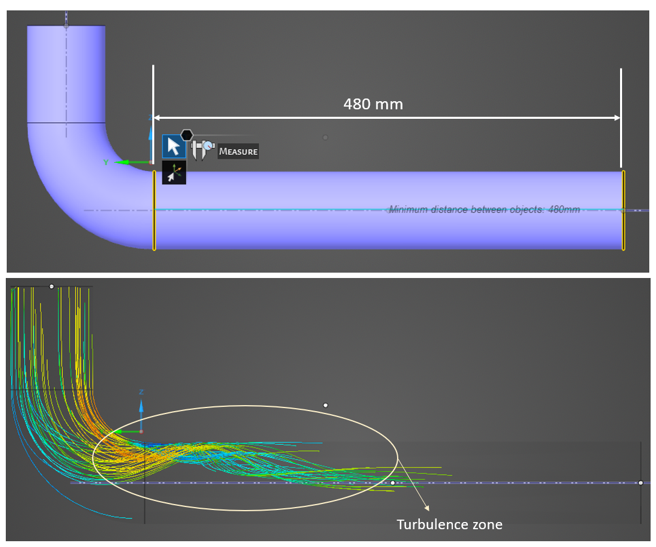

Observing the fluid’s behaviour as it traverses the elbow curve provides insights into its influence on both speed and pressure dynamics.

The fluid exiting the elbow will exhibit turbulent, non-linear, and rotating flow characteristics. This rotational behavior induces swirling effects, necessitating a sufficient length of pipe following the elbow to establish a stable and uniform flow pattern.

Note: Turbulent fluid poses a threat to centrifugal pumps, leading to a reduction in hydraulic efficiency and causing premature mechanical failures.

5. How long should be the pipe?

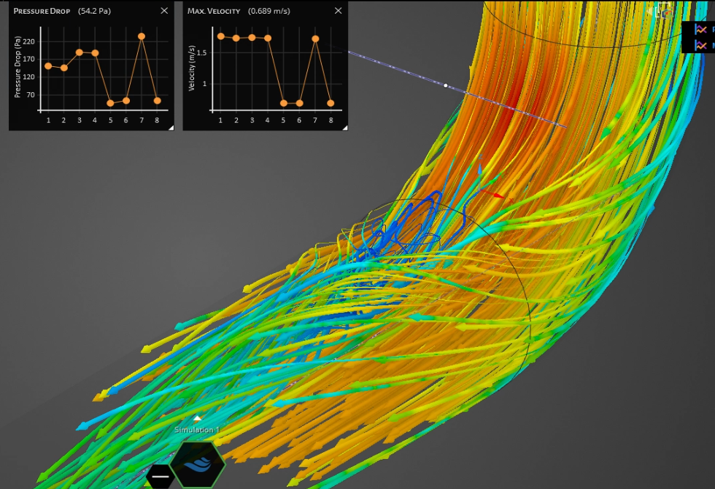

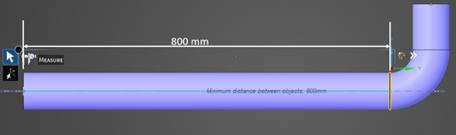

Within this simulation, we quantified the necessary length of pipe essential for achieving a consistent and stable fluid pattern subsequent to its passage through an elbow.

Simulation criteria :

- Fluid: Water

- Pipe diameter: DN80

- Velocity entering the elbow: 1.1m/s

- Pressure entering the elbow: 1.5bar

- Flow pattern entering the elbow: Linear, no turbulences.

- Flow rate: measure @ 2.78kg/s + measure @ 5.56kg/s

The requisite straight pipe length to ensure a consistent and satisfactory flow for the suction port is determined to be 800mm or 10 times the pipe diameter (DN80).

Below are the simulations conducted at varying intermediate distances:

6. Symptoms of pump operating under turbulent flow conditions

When a pump is operating with turbulent fluid, several distinct symptoms may become apparent, indicating potential issues or challenges in the system. Turbulent flow in a pump system can be characterized by chaotic, irregular fluid motion, and the following symptoms may be observed:

- Excessive Vibration: Turbulent flow can lead to increased vibration within the pump and associated piping. Excessive vibration may be felt or observed in the pump housing and surrounding components. This heightened mechanical activity can result in premature wear and tear on pump internals.

- Noise and Cavitation: Turbulent fluid flow can generate increased noise levels, often resembling a turbulent or choppy sound. Additionally, the risk of cavitation rises, causing the formation and collapse of vapor bubbles within the pump. Cavitation not only contributes to noise but can also lead to erosion of pump components.

- Inefficient Energy Consumption: Turbulent flow can impact the overall efficiency of the pump system. The irregular fluid motion may lead to increased resistance, requiring the pump to work harder to maintain the desired flow rates. This inefficiency can result in higher energy consumption and operational costs.

- Temperature Fluctuations: Turbulent flow can cause fluctuations in fluid temperature due to increased friction within the pump system. The elevated levels of turbulence may lead to a rise in fluid temperature, potentially affecting the performance and lifespan of both the pump and the fluid being transported.

- Increased Wear and Tear: The chaotic nature of turbulent flow can accelerate the wear and tear of pump components. Abrasion, erosion, and fatigue may occur at an accelerated rate, reducing the overall longevity of the pump and necessitating more frequent maintenance.

- Pressure Fluctuations: Turbulent fluid flow can result in variations in pressure within the pump and associated piping. Rapid pressure fluctuations may compromise the stability of the system, affecting its ability to deliver consistent and reliable performance.

Monitoring these symptoms is crucial for identifying and addressing issues related to turbulent fluid flow in a pump system. Regular inspection, maintenance, and adjustments to the system parameters may be necessary to mitigate the impact of turbulent flow and ensure the pump operates optimally.

7.Conclusion

In the intricate world of pumping systems, attention to detail is paramount. The danger of placing elbows too close to the pump suction port cannot be overstated. By following best practices in pump suction piping design, engineers and operators can minimize the risks associated with cavitation, vortex formation, and increased NPSH requirements. A well-designed system not only ensures the efficient operation of the pump but also contributes to the longevity and reliability of the entire fluid handling system.