Introduction

A suction diffuser is a component often used in fluid handling applications for centrifugal pump station such as heating or chilled water plants. Suction diffuser is a quick and easy device to protect circulating pump against potential pump cavitation issues. Its primary function is condition flow pattern to enhance pump efficiency and reliability. Pump which are subjected to turbulent flow tends to exhibit operations. This device is typically installed at the suction side of a pump, serving as a combined strainer and flow stabilizer.

1. What is Suction Diffuser

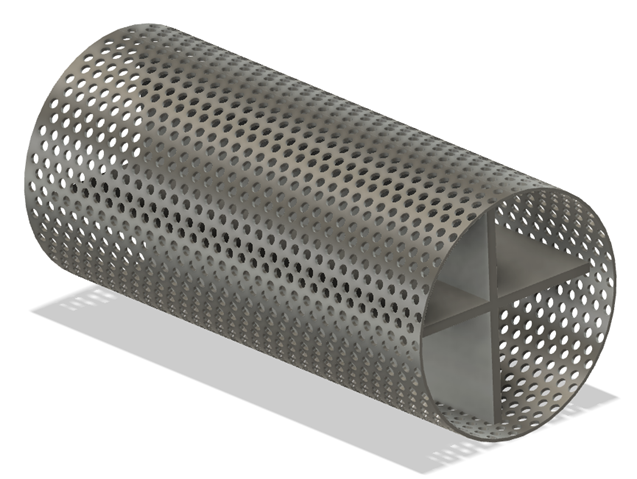

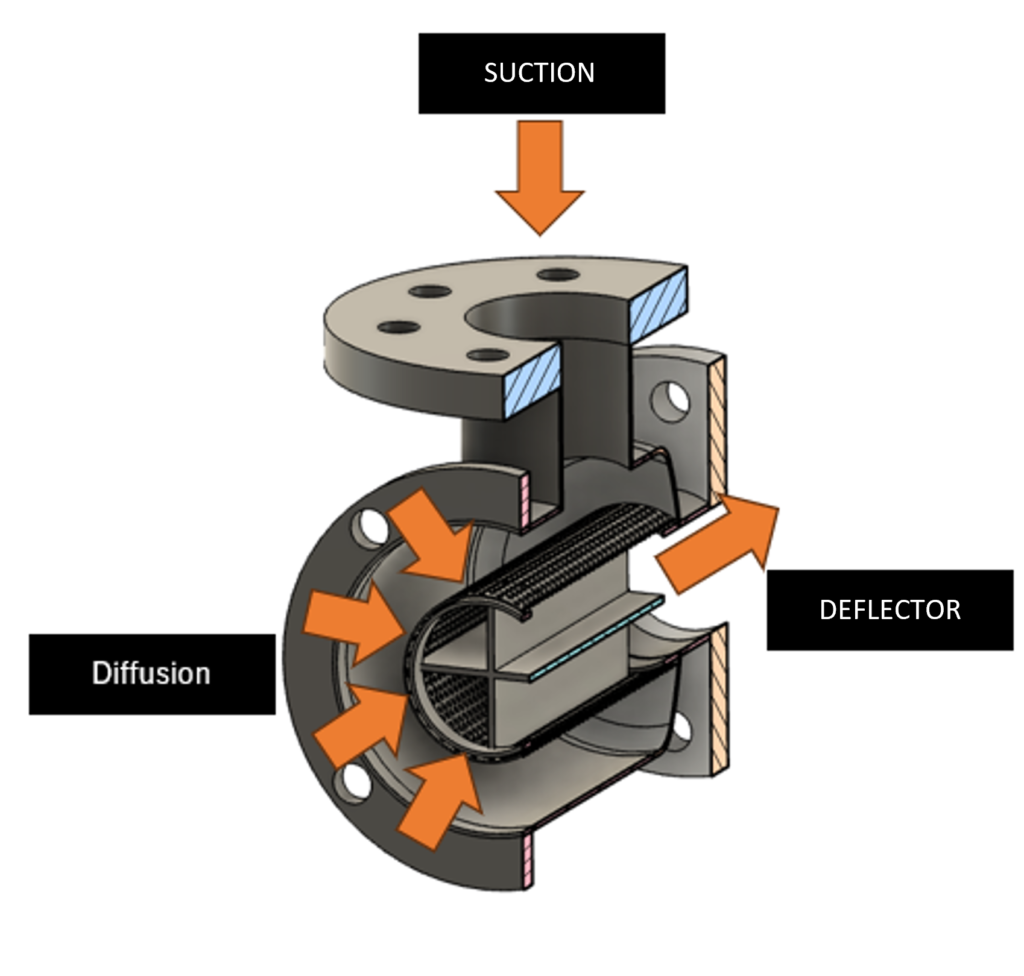

A suction diffuser is a moulded part, made of cast iron or cast steel, equipped with an internal cartridge, manufactured from stainless steel, which consists of a perforated tube and a stainless-steel deflector.

This component is used to condition the fluid before entering the pump suction port to guarantee a stabilized flow, free of turbulences or vortex. The suction diffuser (SD) can be installed directly on the pump flange or supplemented with a small straight length of pipe to satisfy the alignments of the pipes with the main distribution headers or to make a final reduction for the small pump bore sizes.

2. What is the role of a suction diffuser

The suction diffuser brings several benefits to the mechanical contractor in creating its pump suction pipework. The by-product of installing a suction diffuser is the reduction of space required in plant room for the pumping installation and the reduction of cost.

However, its main purpose is to condition the fluid before entering the pump suction port to guarantee the pump’s hydraulic performance, without requiring a straight pipe length, usually recommended between 5 and 10 times the diameter of the suction pipe line.

Suction diffuser technology help to achieve 2 very important tasks, which are, lowering fluid velocities in the suction line and straightening fluid particles.

3. The benefit of Lowering fluid velocity in pump suction line

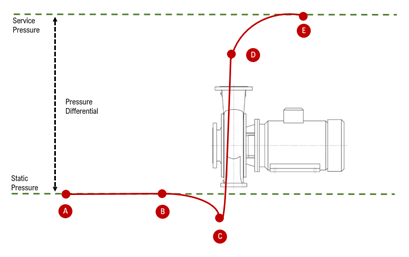

One of the critical constraints when designing pump suction pipework is sizing it correctly. The pump will generate a significant depression in the suction line, the suction pull created by the pump impeller increases fluid velocity and therefore lower the pressure. This high-velocity area is particularly sensitive to poor suction line design which is one of the causes of cavitation.

High Velocity = Lower pressure

It is therefore critical for the suction pipework to be correctly sized to minimize pressure losses and guarantee a satisfactory fluid volume or fully flooded suction. It is also vital that the fluid which entering the pump is free of turbulences, that is to say, a fluid that is not rotating, showing any vortices or recirculation.

This is the reason why it is strongly recommended not to minimise pipe tapping near the pump suction port and leave enough straight length of pipe after the elbow so that the fluid stabilizes.

It is also paramount to ensure that the filter upstream in the suction line is regularly cleaned to avoid any elements that could exacerbate the suction pressure drop.

4. The diffusion effect

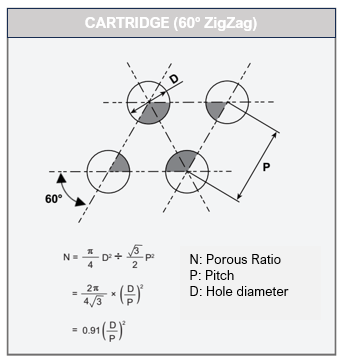

The suction diffuser’s internal cartridge is meticulously designed with specific hole diameters, positions and angles, based on each suction diffuser permissible fluid bandwidth and transmission area.

The fluid entering the diffuser is distributed all around the cartridge and travels via the perforations. This is what is called a diffusion effect because the flow is separated like going through a sieve. This process reduces the fluid velocity entering the suction diffuser’s body, which boosts the suction line pressure.

Note: It is not unusual for us to be called on sites with pump cavitation issue and the simple installation of a suction diffuser in lieu of the elbow is sufficient to resolve the cavitation problem.

5. Fluid simulation of diffusion effect

Reduced Velocity = Increased pressure

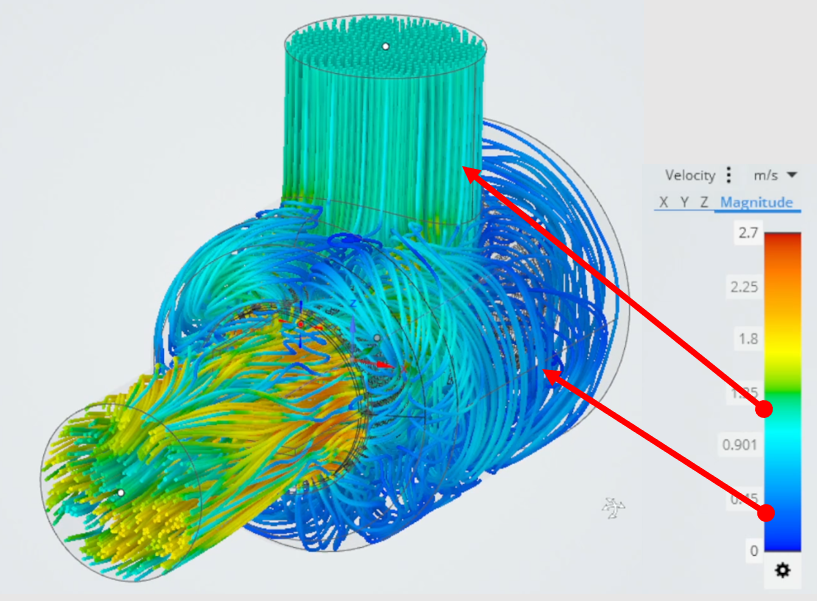

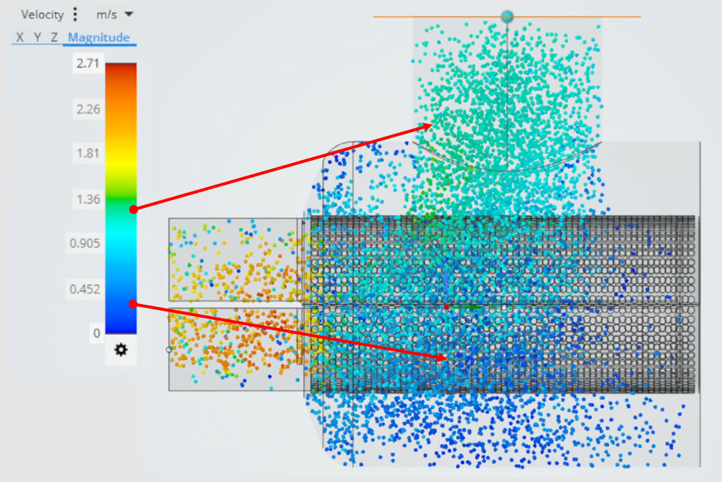

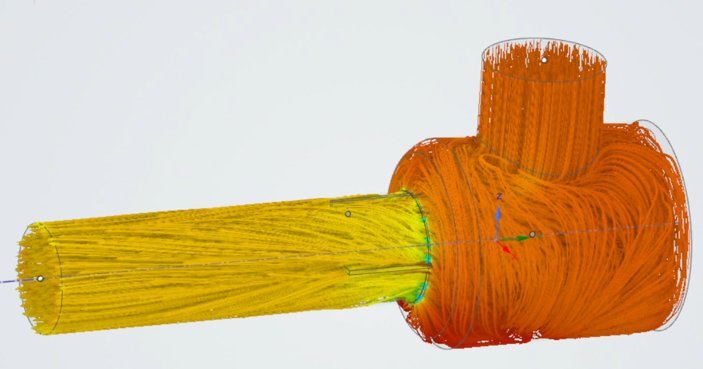

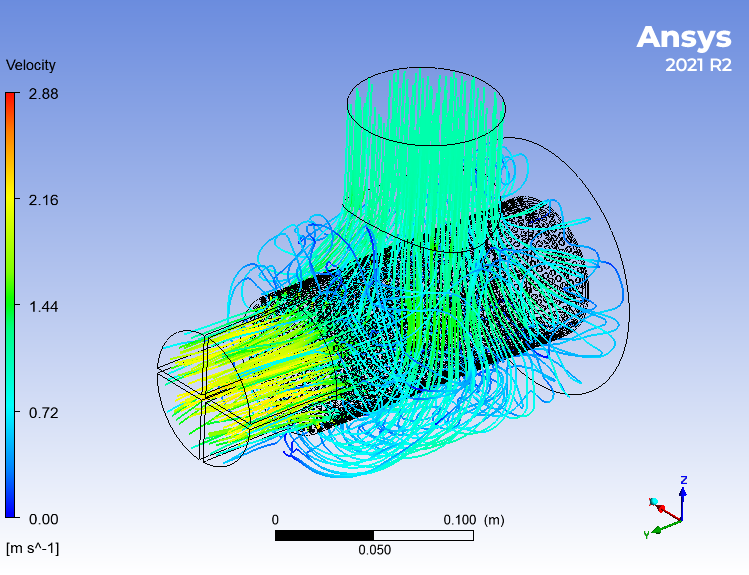

In order to evaluate the impact of the fluid diffusion effect via the perforated cartridge, these are two illustrations of our CFD studies.

In illustration (1), we have a complete SD with its cartridge and its deflector. In illustration (2) the SD only includes the deflector without its cartridge.

Illustration (1): We notice in this illustration a drop in velocity around the cartridge. The particles change colour from green to blue, we can assess the speed on the graduation in m/s.

Illustration (2): This illustration, without a cartridge, shows that the speed of the fluid continues to evolve in the body of the diffuser without interruption right up to the diffuser the outlet port. We can asses the speed on the graduation in m/s.

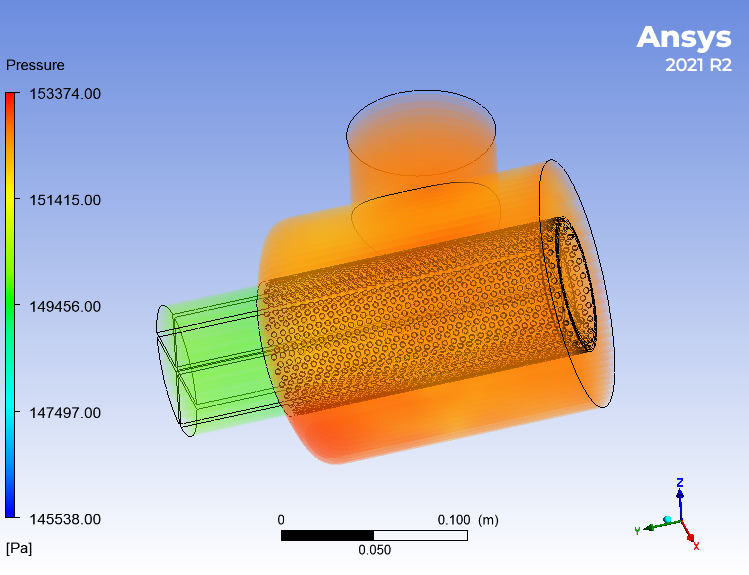

6. Pressure Effect

The increased pressure in the suction diffuser helps to compensate for the depression created by the pump pull in its suction line. The diffusion effect of the cartridge reduces the velocity of the fluid and channels the static pressure into the body of the diffuser.

Note: Reducing the fluid velocity promotes increased pressure in the suction line and minimizes the risk of pump cavitation.

7. Straightening of fluid particles:

The baffle at the center of the cartridge helps straighten fluid particles that become distorted when the fluid changes direction. The deflector prevents the formation of vortices in the fluid and rotation.

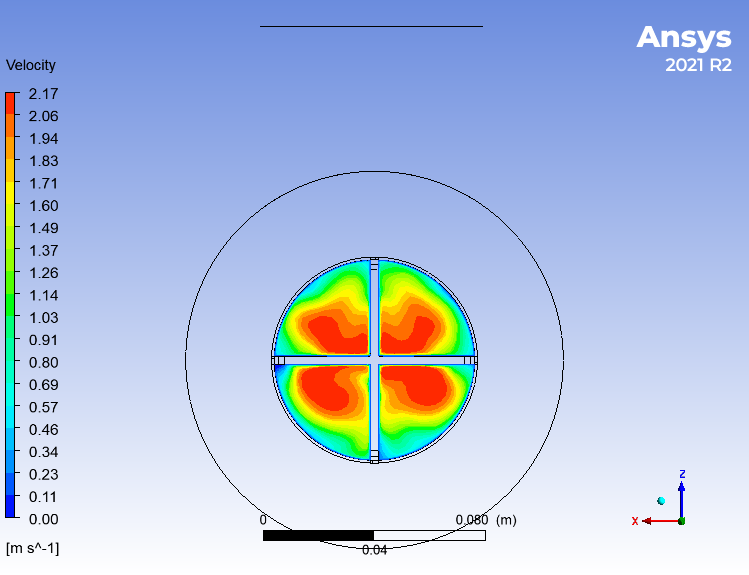

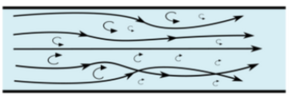

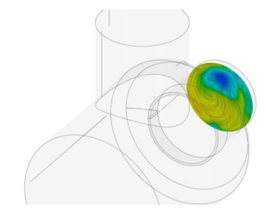

We can observe the fluid particles straightening capabilities at the suction diffuser outlet port. The flow exits the diffuser in the same direction, in parallel layers and with minimum interference between layers. There is no presence of vortex or recirculation effect. The flow leaves the diffuser with a uniformity index of 95%.

The velocity profile shows the formation of stable and predictable layers. We consider the fluid linear with the highest velocity at the center of the pipe and a reduction in velocity as we approach the pipe walls due to friction losses.

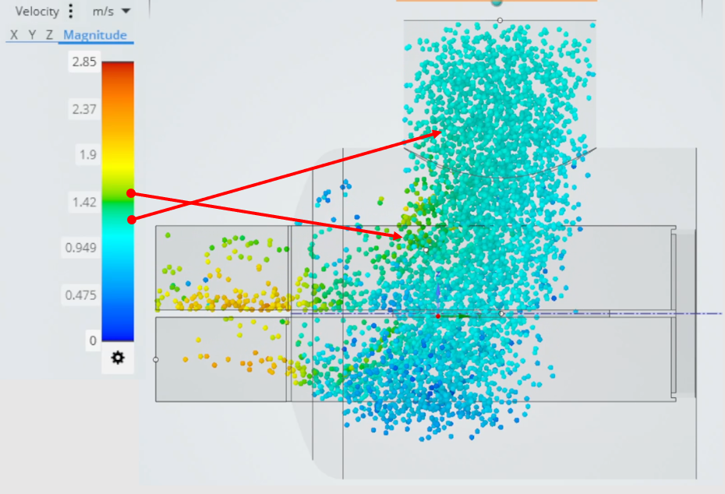

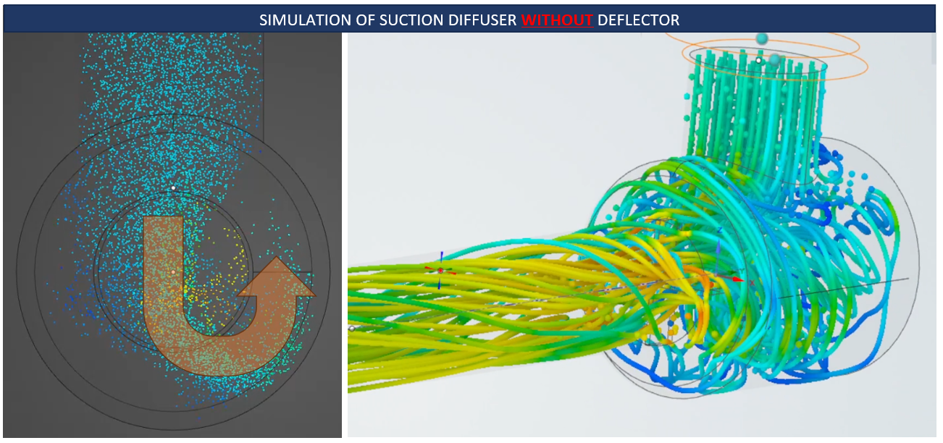

8. The effect of the deflector

For comparison, the image below shows the suction diffuser without a deflector. We can see the fluid rotating as it enters the suction diffuser’s body. The flow becomes turbulent at the outlet port, with chaotic and inconsistent velocity layers.

9. Conclusions

Using a suction diffuser in the pump suction pipe works provides a complete fluid conditioning solution without the inconvenience of implementing a straight pipe length on the suction line. This means great protection against pump cavitation and complete freedom with pipe layout in plant rooms.

Suction diffuser reduces pump installation cost and provide a fully compliant installation according to the European standard CEN/TR 13932 :2009.